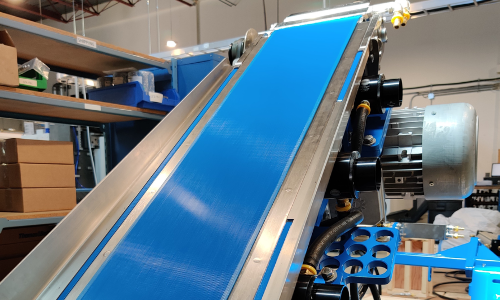

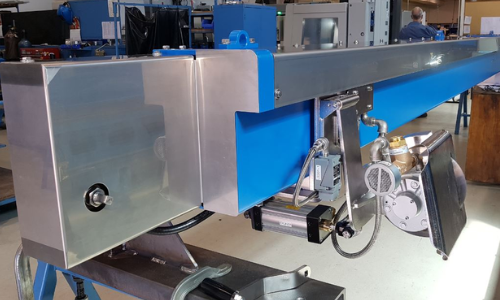

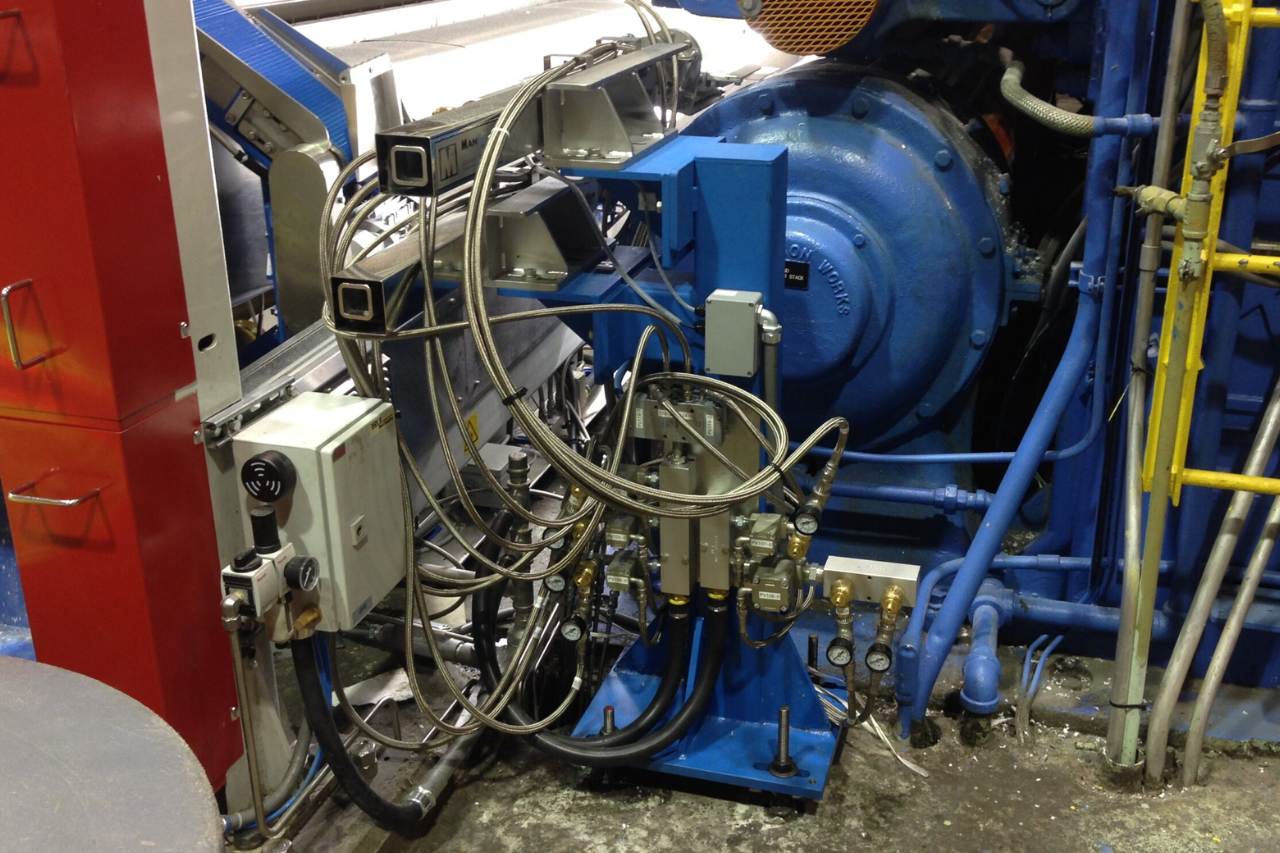

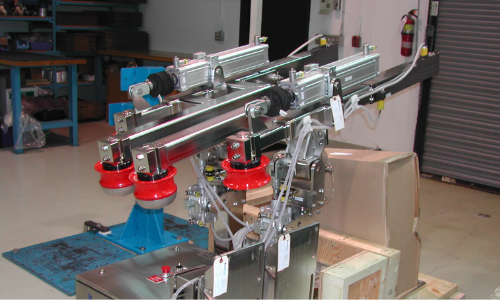

Rope Diverter

Applicable for scanners, edge markers or size press rope removal, this diverter allows full sheet scanning, rope clearance with splasher pans, etc. It lifts rope off rotating rolls when the rope system is in idle or stop mode. Configurable with single, double or three rope systems, for standalone implementation, or can be tied into the paper machine control system.

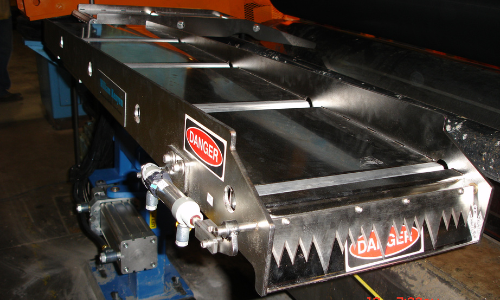

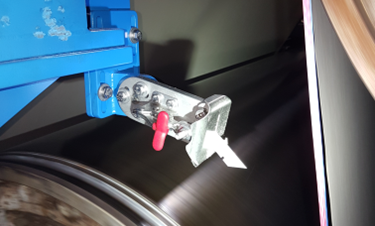

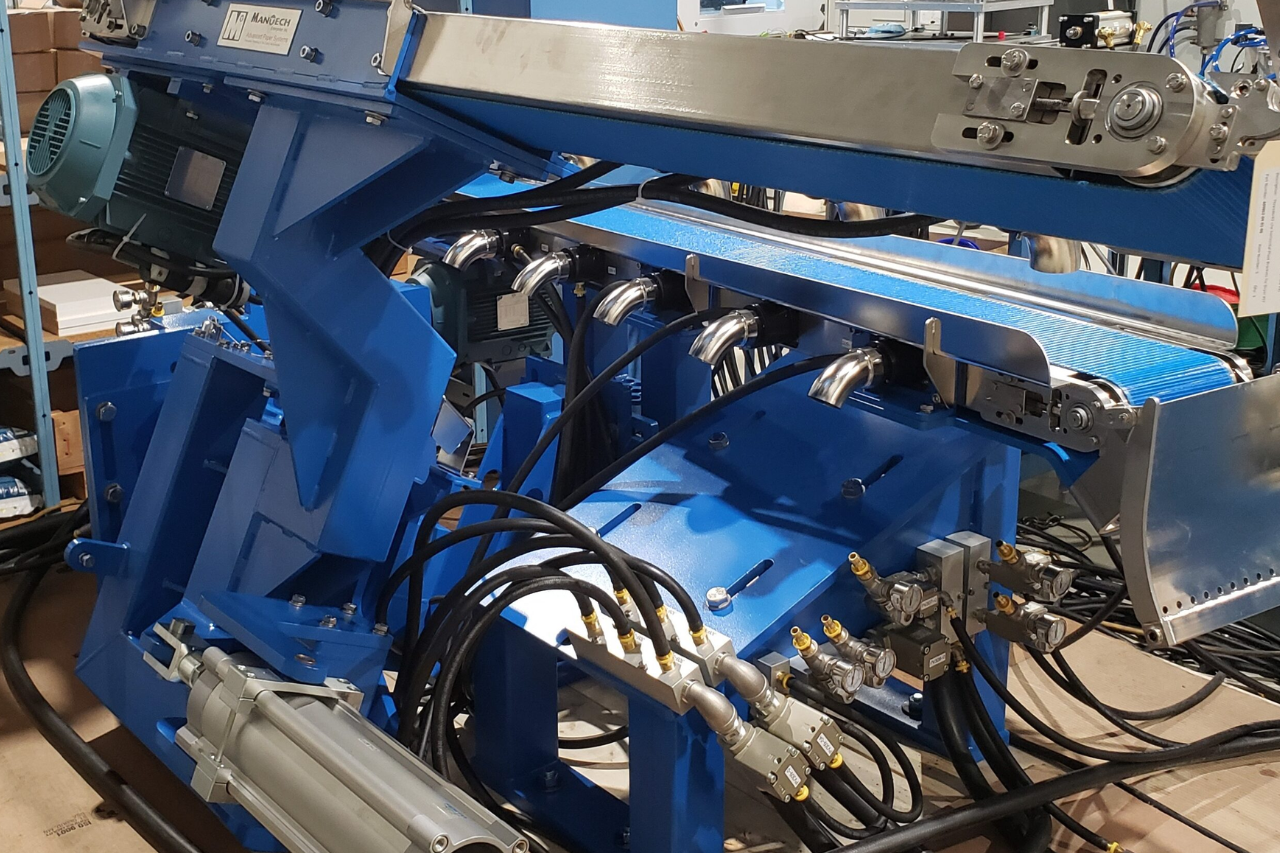

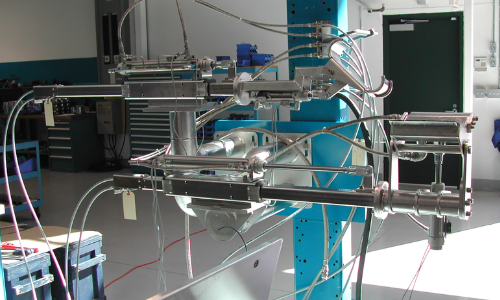

Automated Mechanical Hand

This device simulates a human pulling the tail into a rope nip, eliminating the need for a person to go into the machine. It automatically pulls the tail into the ropes, holds the tail for threading, and releases or holds the tail out of the ropes. It is normally used in conjunction with transfer equipment, which takes the tail off a press roll and transfers it into the next machine position.