an inside look at

We want to challenge the boundaries.

We’re passionate about providing precision-manufactured solutions and custom-machined products across diverse industries. A shared curiosity for innovation drives us, and we transform the ordinary into the extraordinary.

Our vision is to make custom-manufactured solutions more accessible throughout the Lower Mainland, while expanding opportunities and growing our presence in automated tail threading systems for the pulp and paper industry.

company story

we’ve been industry leaders since the beginning.

From day one, we’ve pursued growth, innovation, and top-tier service. That ambition has made us a trusted name in precision manufacturing and a leader in paper-mill automated tail threading systems.

1995

Incorporation

Mantech is founded by Al Manser with a vision for quality and innovation, and begins operations with a few machines and a small leased space in North Vancouver.

1998

A pivotal partnership

Arthur DeKleer joins as General Manager and partner, bringing additional insight and expertise to help the company grow.

2001

A New Facility

We move out of our original space into a new lease at 101-55 Gostick Place in North Vancouver, BC, and purchase additional equipment to handle increased demand.

2005

Expanded Capabilities

We further expand our operations with additional leased space at 102-103 50 Fell Avenue to accommodate our waterjet machine.

2008

Assets for Growth

We acquire both the Progressive Paper Systems assets from Wiliam Kenyon North Vancouver and Unit 200 at Gostick Place, strengthening our position in the pulp and paper market.

2011

Advanced Paper Systems

We officially register a new division called Advanced Paper Systems, formally under Progressive Paper Systems.

2018

A New Era of Leadership

Al and Arthur pass the torch to Alan Linsley and Jaime Lux, the new owners of Mantech. Al exits the company, while Arthur remains on in an advisory capacity.

2019

Unified Under One Roof

To streamline operations, we consolidate all activities under an expanded 55 Gostick Place. Around this time, Arthur exits and leaves Alan and Jaime at the helm.

2023

25 Years Strong

We celebrate a quarter-century in business and remain committed to high-quality and outstanding customer service. We introduce 5-axis machining with a DVF-5000.

2025

Ongoing Innovation

We secure accreditations for both AS9100D and CWB W47.1 to pursue projects in aerospace, defense, and structural steel and add a Hermle C22 UP Machining Centre.

we value people.

Behind every project, phone call, or email are individuals who care, create, build, challenge, and inspire. We value the people behind the work — their curiosity, integrity, and commitment to doing things right. The same energy that shows up on the mountain, at camp, or around the patio shapes how we collaborate, solve problems, and deliver for our clients and one another. We’re committed to fostering an environment where everyone feels valued and empowered.

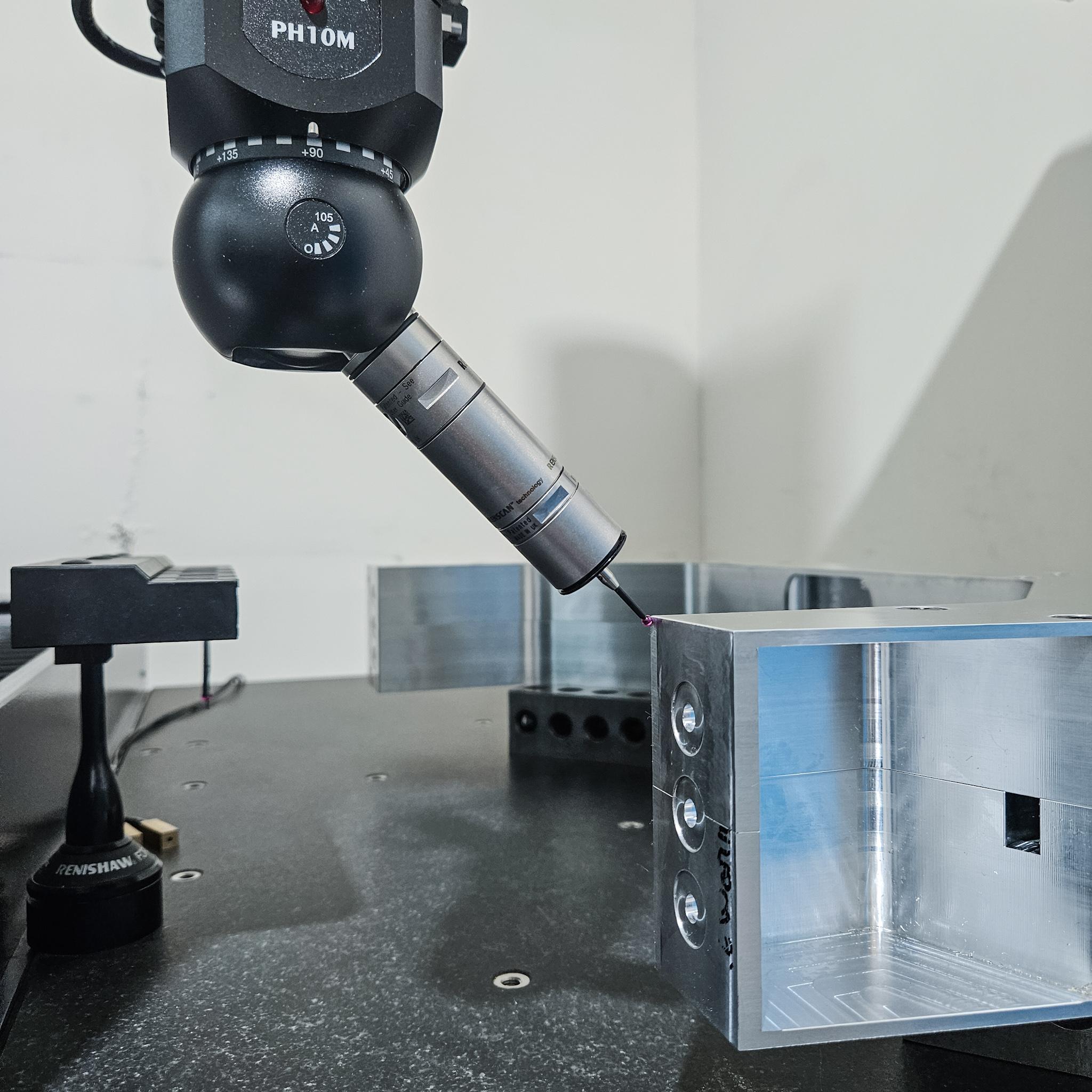

we go above and beyond industry standards.

At every level of our operation, quality and precision are non-negotiable. We proudly hold ISO 9001:2015, AS9100D, and CWB CSA W47.1 certifications. These third-party standards validate that our manufacturing processes, from CNC machining to structural welding, meet rigorous benchmarks for quality, traceability, and safety. Exceeding expectations is just how we roll — check them out below.

We prioritize workplace safety.

We ensure our team follows best practices and uses the correct protective gear on our shop floor. Our safety committee actively works to keep protocols up to date, and each new hire receives thorough safety training during the onboarding process. We encourage our team to speak up if they have concerns or notice any hazards. Safe practices are critical in precision manufacturing and fabrication, protecting both our team and the quality of every product we make.

We contribute to a better tomorrow

At Mantech, we uphold responsible, sustainable business practices that prioritize the environment, our people, and ethical governance. Our leadership team actively oversees environmental and social performance, conducting regular audits and reviews while drawing on stakeholder input to drive continuous improvement in both manufacturing processes and product development.

We follow an ISO 14001-aligned Environmental Management System, focusing on pollution prevention, resource efficiency, and lifecycle thinking.

People and communities are essential to our success. We engage our team to promote safety, inclusion, ethical labour practices, and community engagement and provide ongoing training and development.

We are dedicated to maintaining ethical oversight and accountability in all our operations by safeguarding data, complying with regulatory requirements, and ensuring transparent communication with stakeholders.

We support our local community.

Supporting our industry and community is a core part of who we are. We collaborate with educational programs to inspire and develop the next generation of talent. By mentoring and employing graduates from programs at institutes like BCIT, we help shape the future of precision machining and fabrication. Additionally, we provide our team with opportunities to expand their skills through our in-house apprenticeship programs.