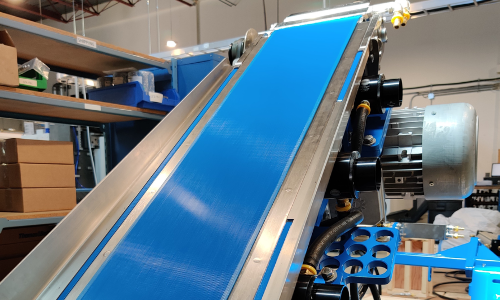

Control, Cut and Transfer

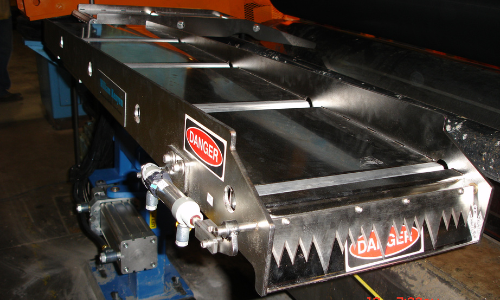

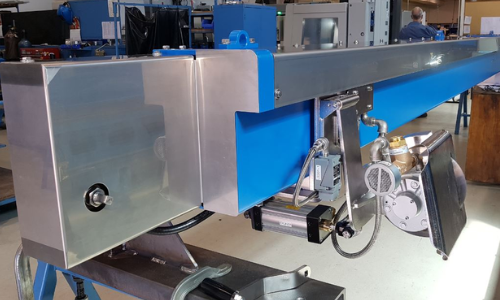

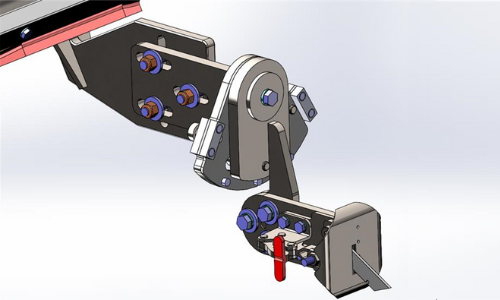

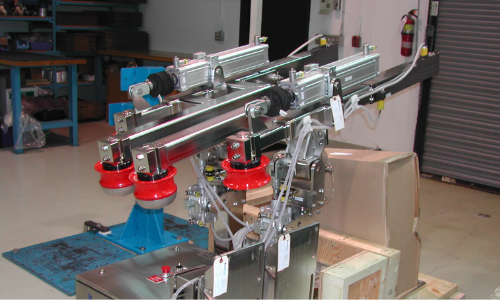

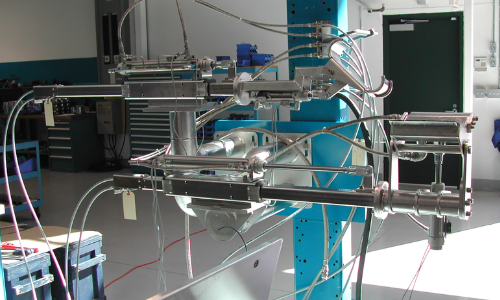

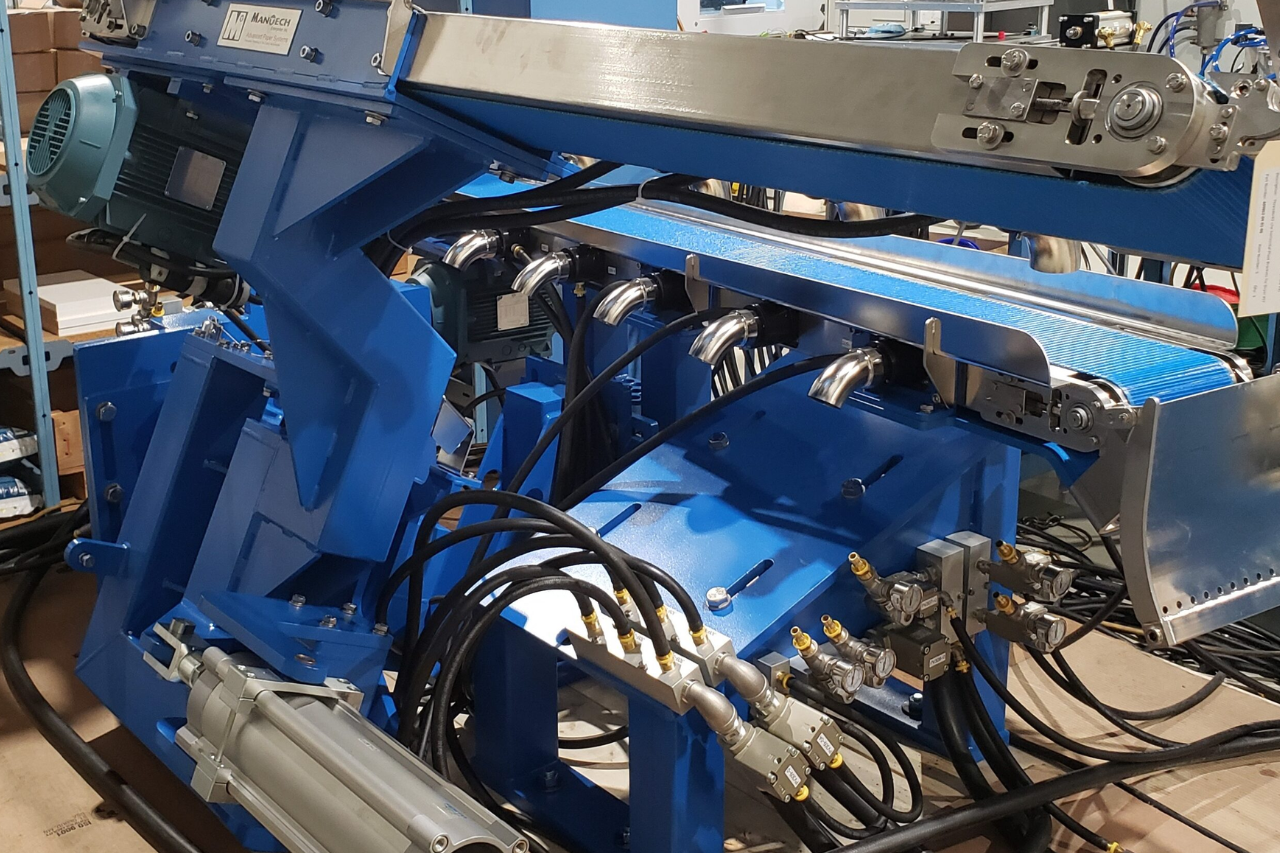

These are the steps for successful tail threading. When a sheet break happens, the first important task is to gain control over the tail being threaded and position it properly. When control is achieved, a fast and controlled cut sets the tail up for a successful transfer. The freshly cut tail is then transferred using a custom designed vacuum conveyor system into the next section of the paper machine. After the tail is completely threaded, a tail cutter positioned downstream moves horizontally across the machine to widen the sheet.