Advanced paper systems, or automated tail threading, are mechanical systems designed to automate the process of guiding of paper tails through paper machines during mill start-up or re-starts. Traditionally done by hand, this task was typically time-consuming, labor-intensive, and posed significant safety risks.

Automated systems use edge doctors, tail breakers, air jets, and conveyors to precisely guide paper tails through machine sections, and allow operators to control everything via control panel from a safe distance. Automated systems greatly improves safety, reduces threading time, and boosts overall operational efficiency.

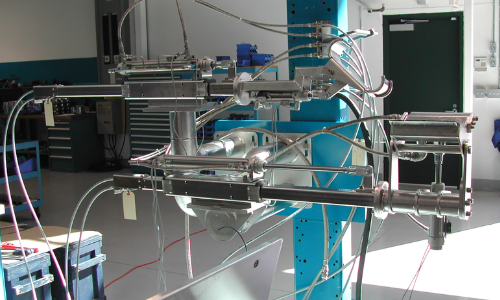

Since automated threading systems require unique designs for different machine sections, we meticulously craft each component to seamlessly integrate with your machine. We place focus on ensuring our designs are robust and of the highest manufactured quality.

Our approach extends beyond just providing the equipment—we pride ourselves on offering a comprehensive full life cycle service from initial design and installation through to after-sales support. This full-service commitment is what our customers value most about working with us.

These are the steps for successful tail threading. When a sheet break happens, the first important task is to gain control over the threaded tail and position it properly. When control is achieved, a fast and precise cut sets the tail up for a successful transfer. The freshly cut tail is then transferred using a customized vacuum conveyor system into the next section of the paper machine. After the tail is completely threaded, a tail cutter positioned downstream moves horizontally across the machine to widen the sheet.

Our footprint in the pulp and paper industry is truly global. Our solutions are trusted by leading mills worldwide to enhance safety, productivity, and efficiency. This extensive reach reflects our commitment to innovation, customer satisfaction, and technical excellence—wherever in the world our clients operate.

We take pride in offering a personalized, small-company experience throughout the design and creation of your equipment while building a long-lasting relationship. Our dedication to your success is reflected in the trust of our many repeat customers. If challenges arise, we’re here to help and always willing to go the extra mile to ensure your satisfaction.

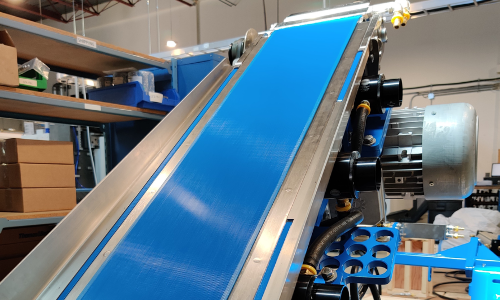

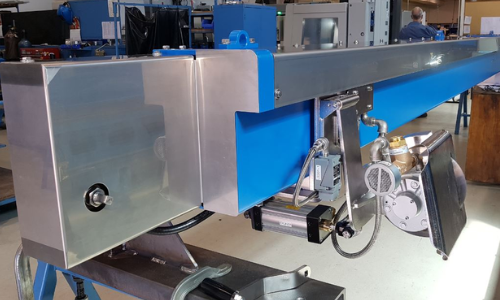

Our continuous vacuum conveyor handles everything from high-speed lightweights to market pulp. It offers horizontal, vertical, and inverted press-to-reel positioning for versatile control and efficiency, all built in stainless steel for reliable, low-maintenance performance.

The air foil threader can operate standalone or with vacuum conveyors and is adaptable for various machine areas—from dryer to reel. Its durable, stainless steel design supports horizontal, vertical, and inverted configurations and is available with tube-type air jets or air knife applications.

Designed for three to eight roll stacks and high-speed lightweights to board, the calender threader eliminates the need for an upper pinch roll, reducing equipment needs, roll wear, and refinishing. It efficiently utilizes compressed air with air knife applications.

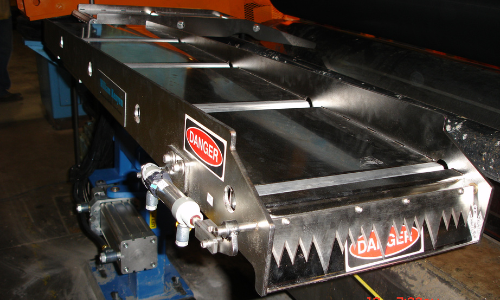

Ideal for tissue, towelling, high-speed newsprint, or press section threading, the SBB tail breaker features a compact, low-maintenance design with a hardened, stainless-steel saw-spike tooth blade. Pneumatic controls ensure safe storage when not in use.

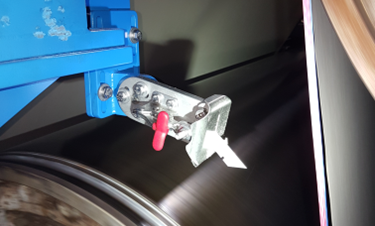

The SGC tail cutter offers a simple, low-maintenance solution for high-speed tail breaking, ensuring clean, straight cuts whether used alone or alongside an edge doctor.

This versatile tail cutter features single, dual, or portable handheld control options and a compact, rigid beam design that allows unlimited cross-machine length with adjustable positioning. Special tooth designs minimize dust and prevent fiber build-up.

Constructed entirely of stainless steel, the water jet tail cutter can work with either a customer or new water supply system. It provides fully adjustable, accurately set cut positions, with options for double or single nozzles and edge trim squirts.

Featuring a compact, rigid beam design for unlimited cross-machine length, the knife blade tail cutter offers fully adjustable or preset cut positions for precision. It allows tool-free blade changes, with the head designed for easy parking and an integrated sheet stabilizing plate.

The rope diverter is designed for scanners, edge markers, or size press rope removal, enabling full sheet scanning and rope clearance from rotating rolls during idle modes. It is configurable for single, double, or triple rope systems, either standalone or integrated with the paper machine control system.

Simulates a human pulling the tail into a rope nip and eliminates the need for manual intervention by automatically pulling, holding, and releasing the tail. It is typically used alongside transfer equipment to move the tail from a press roll to the next machine position.

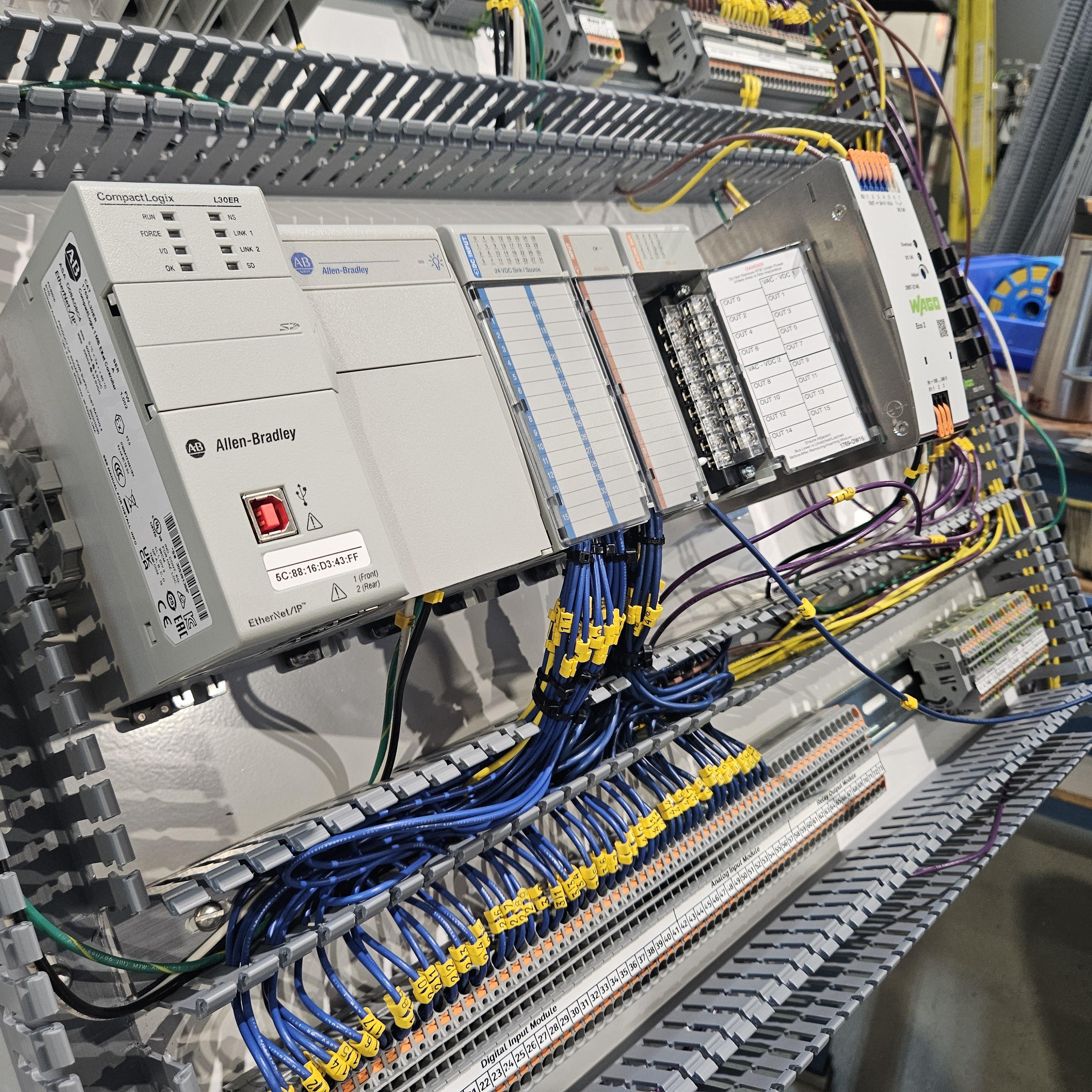

All our threading systems, tail cutters, rope diverters, and automated mechanical hand units come with comprehensive, custom-designed control packages—including operation stations, control panels, and drive panels. Every system is CE certified to ensure safe and reliable operation.

Through years of experience with a wide range of clients, we’ve developed a collaborative approach to our services. We’re here to support you until you’re completely satisfied.

Through years of experience with diverse clients, we’ve honed a deeply collaborative approach to our services. Our commitment to you extends until you’re fully satisfied.

We reach out to discuss your current process and identify any issues you’re experiencing. We then determine which products are needed, along with your machine details and requirements, and propose a solution.

After gathering detailed machine dimensions and application constraints, we work closely with our design team to develop a unique solution to fit your needs. The design is then presented to your users, operations, and maintenance.

Once your threading components have shipped and arrive at your mill, we collaborate with you and any applicable trades on-site to provide system tuning and ensure a successful installation.

Following installation, our dedicated service technicians are available on-site, through video conferencing, or via phone to address any questions or issues. We also provide spare parts as required.

Our agents are located worldwide and would love to help you find the perfect solution for your application.

Drew Thibodeau

Phone: 506 545 6246 / 506 545 8458

Email: [email protected]

Territories: New Brunswick, Nova Scotia, Newfoundland, and Prince Edward Island

Mantech Enterprises

Phone: 604 936 4217

Email: [email protected]

Territories: Alberta, British Columbia, Saskatchewan, and Manitoba (Western Region)

Pierre Chabot

Phone: 514 990 2423

Email: [email protected]

Territory: Québec

Stéphane Guenette

Phone: 450 581 9156 / 514 942 1106

Email: [email protected]

Territories: Manitoba (Eastern Region), Ontario, and Québec

Daryll Benn

Phone: 610 909 4622

Email: [email protected]

Territories: Connecticut, Delaware, Indiana, Kentucky, Maine, Maryland, Massachusetts, Michigan (Eastern Region), New Hampshire, North Carolina, New Jersey, New York, Ohio , Pennsylvania, Rhode Island, Vermont, and Virginia

James Cooley

Phone: 920 819 3414

Email: [email protected]

Territories: Illinois, Iowa, Michigan (Upper Region), Minnesota, and Wisconsin

Mantech Enterprises Inc.

Phone: 604 984 9906

Email: [email protected]

Territories: Arizona, California, Oklahoma, Oregon, Mississippi, Montana, Idaho, and Washington

Mark Dal Ponte

Phone: 229 561 3200

Email: [email protected]

Territories: Alabama, Florida, Georgia, South Carolina, and Tennessee

JB Calhoun

Phone: 205 461 7674

Email: [email protected]

Territories: Arkansas, Louisiana, Oklahoma, and Texas

Alberto C. Benevides

Phone: +57 2 5241700, ext 104 & 105

Email: [email protected]

Territories: Colombia, Ecuador

Alvaro Meleiro Jr.

Phone: +55 19 3523 7587 / +55 19 9 8149 9988

Email: [email protected]

Territory: Brazil

Andres Flores

Phone: +56 75 2322033 / +56 9 89011471

Email: [email protected]

Territory: Chile

陳裕鼎 Andy Chen

+886910129144

Email:[email protected]

Territory: China

Guus Brummel

Phone: +31 525 652351

Email: guusbrummel@henkdebruyn

Territories: Belgium, Netherlands, and Luxembourg

Oleg Plakidin

Phone: +7 812 3478851

Email: [email protected] / [email protected]

Territories: Belarus, Baltic States, Kazakhstan, Russian Federation, Ukraine

Navnit V. Garg

Phone: +91 141 4019047

Email: [email protected]

Territories: India, Nepal

Sjamsuwar Gunawan

Phone: +62 21 546 0935 / +62 21 546 0936 / +62 811 997399

Email: [email protected]

Territories: Indonesia

Surawut Komsuntia

Phone: +66 02 662 8013 14, 02 662 8020 21 / +66 94 251 1973

Email:[email protected]

Territories: Thailand

Mantech Enterprises

604-984-9906

Email: [email protected]

Territory: Australia and New Zealand

Our agents are spread out around the world, and look forward to helping find the perfect solution for your needs.

Drew Thibodeau

Phone: 506 545 6246 / 506 545 8458

Email: [email protected]

Territories: New Brunswick, Nova Scotia, Newfoundland, and Prince Edward Island

Mantech Enterprises

Phone: 604 936 4217

Email: [email protected]

Territories: Alberta, British Columbia, Saskatchewan, and Manitoba (Western Region)

Pierre Chabot

Phone: 514 990 2423

Email: [email protected]

Territory: Québec

Stéphane Guenette

Phone: 450 581 9156 / 514 942 1106

Email: [email protected]

Territories: Manitoba (Eastern Region), Ontario, and Québec

Daryll Benn

Phone: 610 909 4622

Email: [email protected]

Territories: Connecticut, Delaware, Indiana, Kentucky, Maine, Maryland, Massachusetts, Michigan (Eastern Region), New Hampshire, North Carolina, New Jersey, New York, Ohio , Pennsylvania, Rhode Island, Vermont, and Virginia

James Cooley

Phone: 920 819 3414

Email: [email protected]

Territories: Illinois, Iowa, Michigan (Upper Region), Minnesota, and Wisconsin

Hung Nguyen

Phone: 650-670-0922

Email: [email protected]

Territories: Arizona, California

Mantech Enterprises Inc.

Phone: 604 984 9906

Email: [email protected]

Territories: Oklahoma, Oregon, Mississippi, Montana, Idaho, and Washington

Mark Dal Ponte

Phone: 229 561 3200

Email: [email protected]

Territories: Alabama, Florida, Georgia, South Carolina, and Tennessee

JB Calhoun

Phone: 205 461 7674

Email: [email protected]

Territories: Arkansas, Louisiana, Oklahoma, and Texas

Guus Brummel

Phone: +31 525 652351

Email: guusbrummel@henkdebruyn

Territories: Belgium, Netherlands, and Luxembourg

Mantech Enterprises Inc.

Phone: 604 984 9906

Email: [email protected]

Territories: Belarus, Baltic States, China, Indonesia, Kazakhstan, Russian Federation, Thailand, Ukraine

Navnit V. Garg

Phone: +91 141 4019047

Email: [email protected]

Territories: India, Nepal

Alberto C. Benevides

Phone: +57 2 5241700, ext 104 & 105

Email: [email protected]

Territories: Colombia, Ecuador

Alvaro Meleiro Jr.

Phone: +55 19 3523 7587 / +55 19 9 8149 9988

Email: [email protected]

Territory: Brazil

Mantech Enterprises

Phone: 604 984 9906

Email: [email protected]

Territory: Argentina, Chile, Mexico, Uruguay.

Mantech Enterprises

604-984-9906

Email: [email protected]

Territory: Australia and New Zealand